In our last newsletter, we explored the sociological impact of metals, specifically, how the advancement of civilization has come with the discovery and availability of increasingly sophisticated tools. Whether it is bronze weaponry or steel railroad tracks or copper circuitry, the expanded use and distribution of materials has marked the progress of humankind from the Stone Age to modern times. Today, the largest consumers of materials throughout the world are the most advanced countries in North America and Europe, very closely followed by those striving to achieve the same or greater level of affluence throughout Asia and in some areas of Africa and Latin America. Our standard of living, while enviable to those who live with much less, requires an abundant flow of deliverable materials to maintain. We see this in China’s rapid 21st century expansion. At a far greater pace than US development in the 20th century, it requires huge resources to grow food, produce transportation systems, construct homes and offices, and deploy technology. According to USGS Cement Statistics, in the last three years, China has consumed more than three times the amount of cement used in the US during the last 100 years. Raising the standard of living of the world’s developing countries will require the same kind of abundant material resources. It is a trend we can expect to see for many years to come.

This very phenomenon and its impact on the environment is explored in Vaclav Smil’s Making The Modern World: Materials and Dematerialization. An accomplished environmental scientist and historian, Smil chronicles material usage from prehistoric times through to the 21st century and beyond. Included in his study is the increased use of wood, stone, sand and metals, specifically steel, copper and aluminum, as they relate to the growth and modernization of civilization. Steel has a long history in agriculture, industry, transportation and construction, specifically in reinforced concrete, an important material for new bridges, damns and skyscrapers. Expansive demand for copper in the last 150 years started with pipes for indoor plumbing and heating systems and later as a conductor of electricity. Now used in electronics and telecommunications, it is a vital component of growing cities. A relative late-comer by larger historical standards, aluminum production began in earnest in the late 1800’s. Its lighter weight, malleability, tensile strength and corrosion resistant properties make it ideal for the trains, planes and cars that are also part of an expanding economy.

Worldwide demand for these metals is predicted to continue. According to WorldSteel.org, crude steel production has nearly doubled since 2000 and by 2050, steel use is projected to increase 1.5 times over present levels. Global demand for copper is projected to increase 4.2 percent per year through 2019. Primary aluminum has experienced strong global growth in demand over the last 15 years; nearly 5 percent per year; that’s twice the pace of the preceding 30 years. These gains have been driven primarily by China’s aggressive economic expansion. While the country’s rate of growth has slowed recently, long-term projections for demand remain strong across all material categories.

If we are to maintain our standard of living and seek to raise that of developing countries, how do we then mitigate the risk of running out of the resources that fuel growth? What are the environmental consequences for future generations? Smil predicts a future that might include limiting our use of some resources, but clearly notes that engineering fewer materials into product design is not always the answer. Sometimes less yields more. For example, cell phones require less material than a 1960’s mainframe computer, and have within them the same capabilities of a camera, telephone, radio, a game room, music library, navigation system, compass, and alarm clock. It requires significantly less materials to produce all the capabilities, yet because of its relative cost and availability, the dematerialization of cell phones is offset by a proliferation of demand. The same reverse logic could be applied to home construction. In spite of the today’s earth-friendly resource-efficient building trends, we are building homes that are considerably larger on average, 1725 square feet in 1983 compared with 2598 square feet in 2013, negating any material gains.

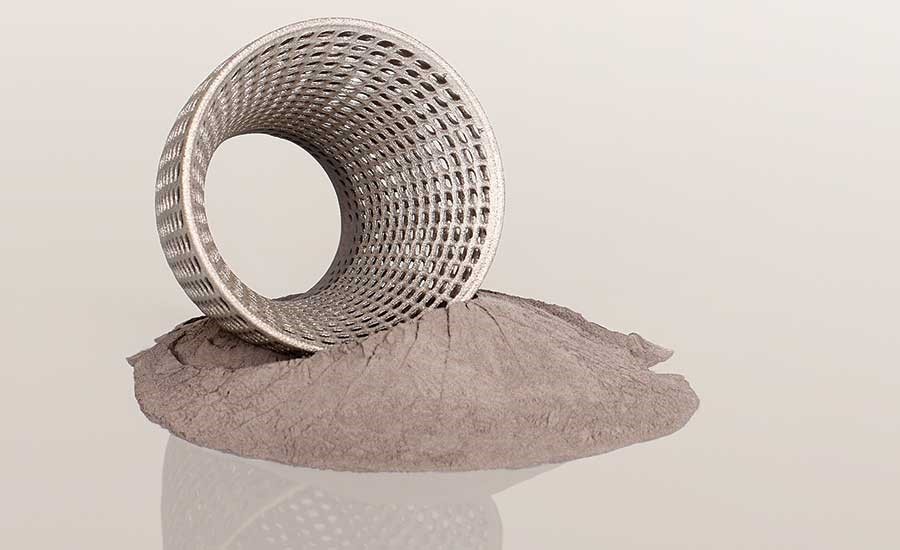

Smil suggests we are not running out of materials any time soon. By reducing yield losses, reusing metal components, building products with an intentional longer life and more rigorous recycling, we can significantly impact consumption. And, of course, scarcity breeds innovation. We are starting to see new materials substituting for more limited resources. Silicon, ceramics and plastics are used in some applications replacing metals. Fiber optic glass cables are replacing copper and aluminum in telecommunications wires. While still in its infancy, gains are being made in nanotechnology, the science of producing materials from atoms and molecules; in the engineering of new metal compounds, alloys and composites; and in additive manufacturing technologies that produce nearly zero waste. These are trends showing no sign of slowing down.

For those of us sensitive to the recent volatility in commodity pricing, this macro view may provide a more sobering long-term perspective.

Looking back, looking ahead; wishing you the very best in business — and a very happy Thanksgiving

![]()

Sources: Making The Modern World: Materials and Dematerialization by Vaclav Smil, Environmental Issues and Solutions: A Modular Approach by Norman Myers, Scott Spoolman, money.cnn.com, US Census Bureau, The Freedonia Group, The CRU Group, The NY Times, The Wall St. Journal, US News & World Report, worldsteel.org

What is the future of the workplace?

This last year and half have been filled with uncertainty whether you are a company owner or an employee working for someone else. During...