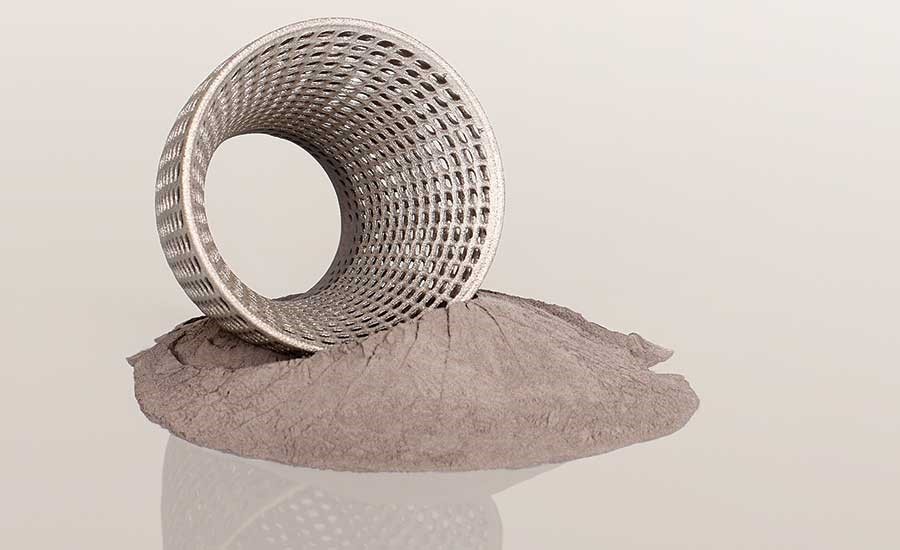

What is 3-D printing and how does it work?

3D printing is a process of manufacturing a 3-dimensional solid object from a digital file using a printer specifically designed for this purpose. The printer will lay down successive layers of material from the bottom up until the object is fully created.

In the metals industry, we are used to subtractive manufacturing, milling out parts of your materials; 3D printing is an additive manufacturing process. Printing this way allows you to produce a complex shape with a limited amount of waste created, unlike subtractive manufacturing.

According to Acumen Research and Consulting, the global 3D printing market is forecasted to reach $41 billion by 2026.

Even if 3D printing won’t work for you on a large scale, it could help you create a rapid prototype. Rapid prototyping is the process of designing and manufacturing a single copy from a 3D printer to test and verify that the product works for your needs.

Can you use metal products with a 3D printer?

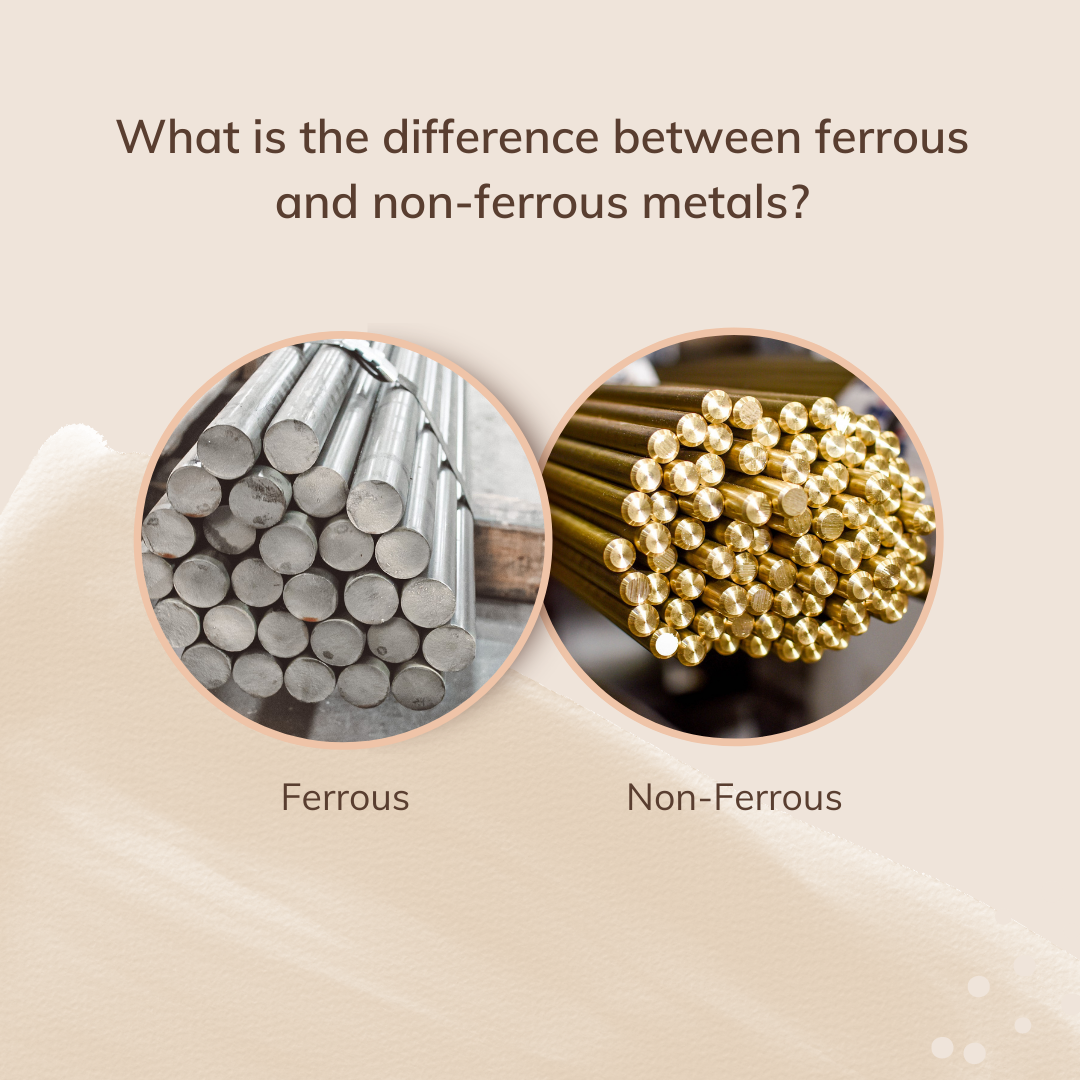

Yes, metals like stainless steel, chrome, aluminum, nickel alloy, titanium, and some steels work in 3D printing. The process is a bit different when using metals vs. other materials, however. Since additive manufacturing forms parts in such a different way, 3D printing works well when producing certain types of parts that require complex features. The process uses no tooling, is almost fully automated, and adds rather than removes material to allow for more optimized geometries, according to Markforged. With a metal 3D printer, a laser beam melts layers of metal powder. This makes metal 3D printing a great fit for parts that might be traditionally very difficult or expensive to manufacture, including legacy parts, line automation tools, and functional cast prototypes.

What is the benefit of?

The benefits of 3D printing your parts are cost savings by limiting the amount of material waste, and time saving. 3D printers can run all night and all day if programmed in advance and left with enough material. This allows low or mid-volume production runs when there are limited funds for prototyping, or if you are a small business, is perfect when you need something less than a full mill run.

What is the future of the workplace?

This last year and half have been filled with uncertainty whether you are a company owner or an employee working for someone else. During...